Description

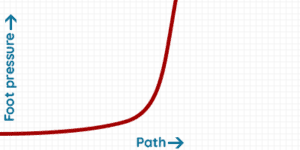

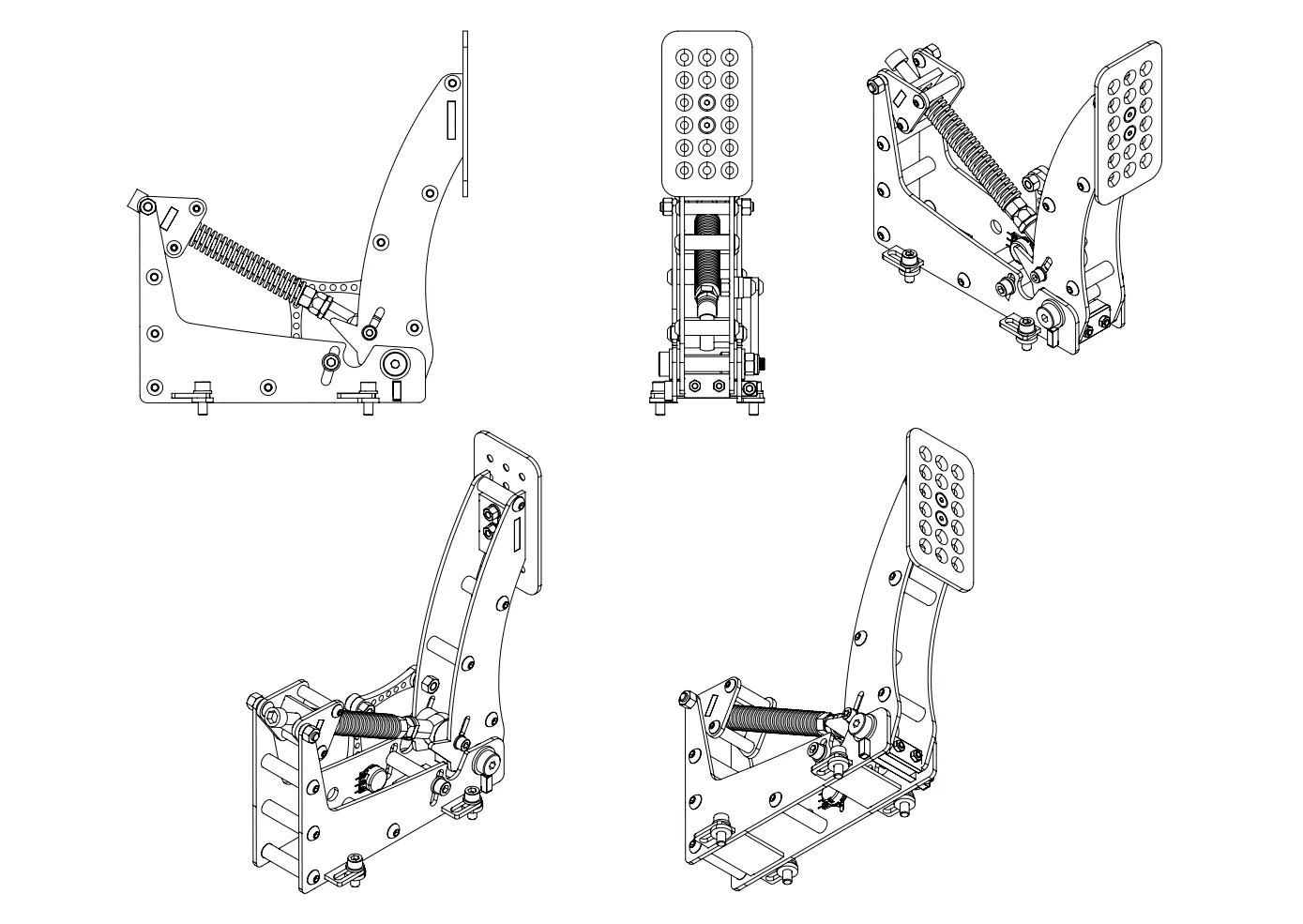

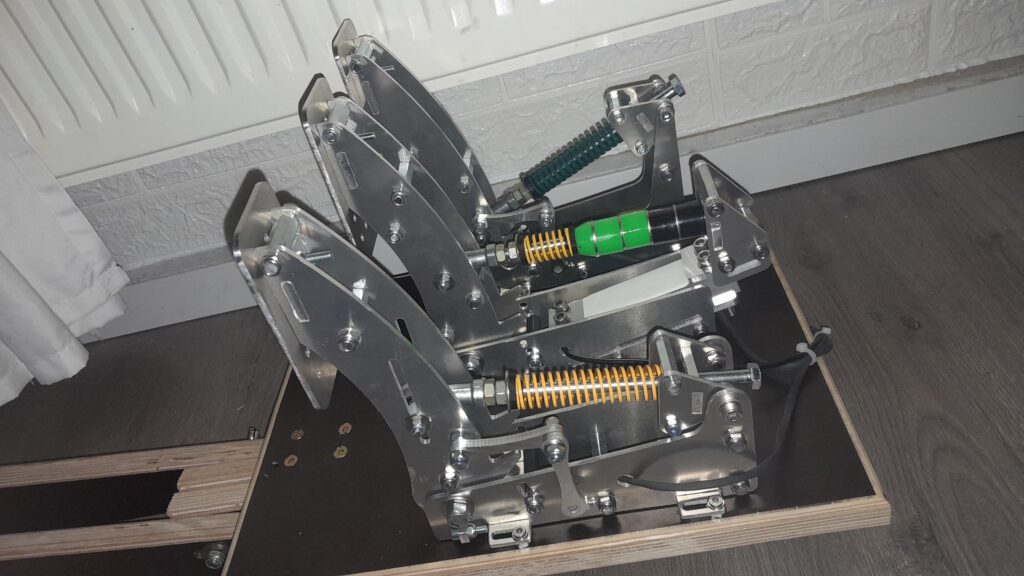

Sim Racing Pedals – Premium CAD Design for DIY Build

Build With ZERO Stress

This DIY pedal kit is designed for makers of all levels. No advanced skills, no specialized tools — just straightforward assembly backed by clear, beginner-friendly instructions. If you can follow a guide, you can build these pedals.

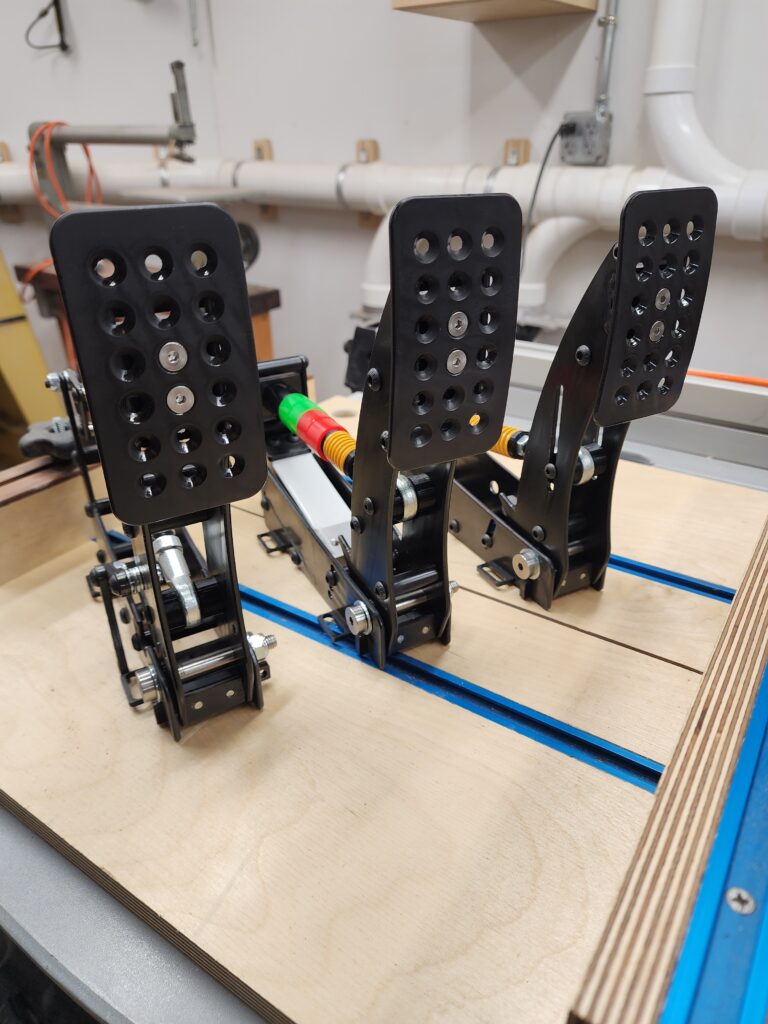

Engineered for Realism

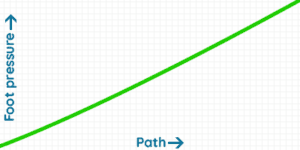

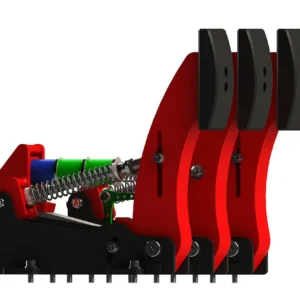

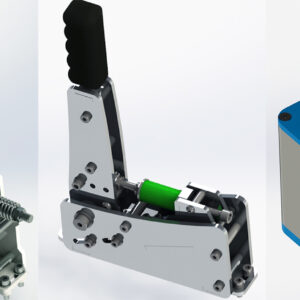

Experience pedal feel that mirrors real motorsport mechanics: linear throttle for smooth, consistent acceleration. Two-stage load-cell brake with soft and firm phases. Degressive clutch that mimics the bite point of a real car.

Every pedal delivers precision you can feel in every corner.

Thoughtful, Professional Design

The aesthetics are inspired directly by automotive engineering. Whether you choose the full-metal fabrication or the 3D-printed edition, the final result looks clean, modern, and built for performance.

Fully Adjustable for Your Driving Style

These load-cell pedals were created for maximum flexibility. Fine-tune the: pedal angle, hardness and resistance, end-stop travel, footrest and pedal positioning.

Dial in your perfect setup, whether you’re drifting, racing GT, or tackling rally stages.

A Budget-Friendly Performance Upgrade

Build high-quality pedals at a fraction of commercial pricing. Cost depends on your chosen materials and tools — 3D printing, CNC, laser cutting — but every option keeps the project accessible and affordable.

Reliable Support Anytime You Need It

If you run into questions or challenges, free assistance is always available in the Help & Questions section. We’re here to make sure every builder reaches the finish line.

DIY Sim Racing Pedals SET

THROTTLE PEDAL

The throttle pedal is linear, you can adjust the hardness, angle, stop and the footrest position. Concerning electronics, it’s a potentiometer fixed by two levers with a very solid structure.

BRAKE PEDAL

Load cell pedals provide precise and realistic braking force, improving your control and immersion in the game. The brake is made up of one spring and many elastomers which enables the two stages of braking: soft then hard.

The feeling is adjusted by changing the combination of elastomers and/or by tightening the spring. The technology is similar to the Handbrake Load cell. The pedal is designed to take more than 100kg of pressure! Concerning electronics, it will be a 120kg pressure sensor.

CLUTCH PEDAL

The clutch is almost similar to the throttle, but has a degressive mechanism allowing to simulate the clutch of a real car (only the 3D Printed Edition is linear).

Throttle Pedal

Brake Pedal

Clutch Pedal

- You are going to buy a file (the CAD models of the Sim Racing Pedals), we don’t sell physical product

- After your purchase, you will be able to download your file in your member area (Account > Downloads)

- This product is protected by Licence. You are not authorized to sell or share it.

BUILDING GUIDE OF THE PEDALS

▶️ Building guide playlist of the Sim Racing Pedals.

▶️ Building guide of the 3D Printed Sim Racing Pedals

SIM RACING PEDALS Parts compatibility

You can use other parts to build this load cell pedals (apart from those listed in the required parts section), but you will need to check that they are compatible.

POTENTIOMETERS

- Ohm: 10k is recommended, but 100k can also work (it depends at the USB Board).

- Thread: between Ø6mm and Ø9mm

- Shaft diameter: not to exceed Ø7mm

LOADCELL

Weight: not below 100kg.

Loadcell dimensions:

ELASTOMERS

- ØInside diameter: min. 8mm, max. 10mm

- ØOutside diameter: not to exceed 35mm.

SPRINGS

- ØInside diameter: not below 8.5mm

- ØOutside diameter: not to exceed 28mm

If you use springs with different dimensions, we advise you to create the spring centralizer part. You will need to download Freecad (it’s a free software) and read the tutorial that is provided. Everything is in the Alternative spring centralizer folder.

ALTERNATIVE FOOTREST:

Material of the DIY racing sim pedals

LASER CUTTING

As for the Sim racing sequential shifter, we recommend stainless steel. For the few parts that need to be machined, we recommend aluminum because it is softer. The parts that require machining are the following:

- Countersinks holes for the Footrests

- Two holes to drill and tap for the potentiometer levers

All these machining operations can be avoided if you use 3D printing alternatives.

The thickness of the plates is only 3mm and 5mm, and it is indicated in the name of the folders.

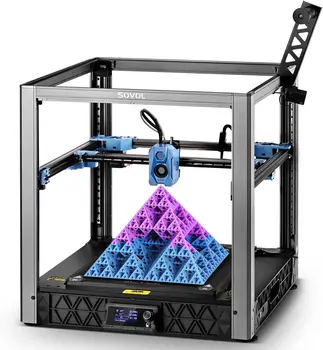

3D PRINTED PEDALS

We recommend PLA or ABS, the filling will vary according to the pieces, and it will be indicated in the name of the files. Here are recommendations for printing 3D solid parts.

HAND CUTTING AND CNC MACHINING

I recommend aluminum because it is a soft metal that is easy to work with.

How to get the required materials

LASER CUTTING

I advise you to use the 3mm and 5mm “All-in-One” DXF files and request a quote from laser cutting companies near your home. All parts are flat, there are none to bend. So you can compare prices and choose the most profitable. On average, the asking price for cutting a stainless steel pedal is between €100 and €150 including VAT and shipping. You can save money if you make a combined order. For France and Europe, I recommend the company ALPM. They provide a very good quality cut for a reasonable price.

3D PRINTED PEDALS

You can buy a 3d printer or find a 3d printing service like treatstock. Don’t forget the infill percentage if you want a strong product (especially for the brake pedal). The longest part that need to be printed is 220mm.

Looking for high-quality 3D printing services? With Treatstock, you can easily get instant quotes from professional manufacturers worldwide. Upload your design today and get your free, no-obligation quote in minutes! 👉 Get Your Quote Now

HAND CUTTING

You need only sheets of papers, printer and Aluminium plates!

CNC MACHINING

I recommend CNC Machining only if you own a CNC Rooter, otherwise it is not economically profitable enough compared to laser cutting.

SCREWS

Bolt depot, Motedis and FixnVis.

Tolerances

- Laser cutting DXF files and CNC Machining files: 0.2mm

- 3D Printing: 0.6mm

Springs and Elastomers

Electronics SHOPPING LIST

- Quantity: 2

- Resistance: 10k Ohm

- Note: you need M8 washer to fix this potentiometer

Arduino Leonardo USB Board (alternative #3)

- Quantity: 1

- Note: compatible only with HX711 Loadcell Amplifier

Arduino Pro Micro USB Board (alternative #4)

- Quantity: 1

- Option: Micro USB

- Note: compatible only with HX711 Loadcell Amplifier

Tools SHOPPING LIST

Find what you need in the DIY Tools section.

He comprado los planos para fabricar los pedales, y se momentos muy bien. Por ponerles alguna pega ws que la documentación, o más bien su organización sería bastante mejorable

Pour l\’instant tout semble parfait, les tutos sont compréhensibles même pour quelqu\’un qui ne parle pas anglais. Le seul bémol est qu\’il faut s\’adapter pour certaines pièces non disponible en France comme les cartes et capteurs de charges et chère à l\’import, heureusement il y a plusieurs entreprises qui en font made in France.

Je précise néanmoins qui je n’ai pas encore commencé l’assemblage des pièces car je fini un volant avant

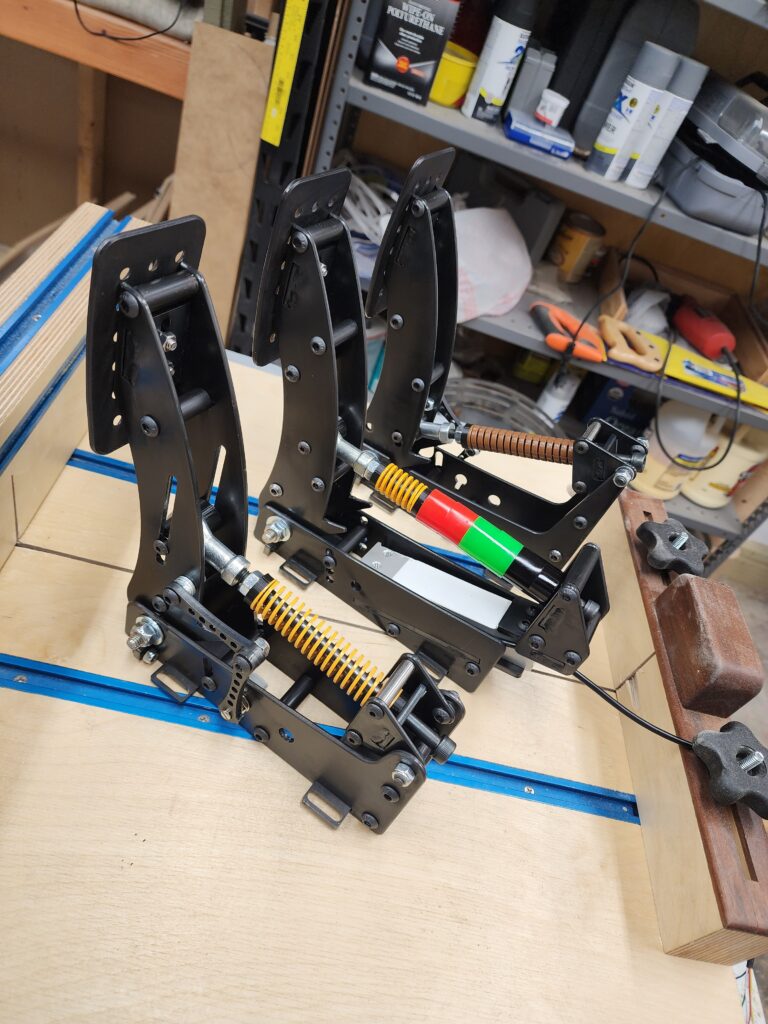

Great set of pedals for the price, easy to build and set up the electronics. Minimal play in the brake pedal due to manufacturing tolerances.

This is excellent pedals, very easy to following steps and complete list of parts needed.

Very impressed with these! Thank you so much for putting together all the documentation and files. I was only able to get 7ga steel here in the states so I adjusted the slots for the difference in size. The pedals went together and installed/calibrated with no problems, after a very speedy response on an issue that ended up being my fault. I used plain carbon steel and then used a black oxide finish with a acrylic finish to protect it. The only thing I “added” or “upgraded” was the spacer for arms that connect the potentiometer, I couldn’t get the joints tight enough that they wouldn’t have any slop but still move freely without sticking. I ended up getting some small M6 thrust bearings off amazon for a few bucks. Now I can tighten the joints snug, and they still are silky smooth. Also make sure to lube the brake M8 bolt where it goes through the elastomer bushings, this pretty much stopped any squeaking from that, and if the throttle or clutch springs squeak, try rotating them a bit to find where they don’t. Worked for me.

Again thank you very much, looking forward to building the handbrake!!

very nice, happy with the pedals. genius Plans, Thank You for your work!

The pedals design is amazing, they look great. And they work as they look. Keep up the good work

Les plans sont au top, je dirai qu’il manque juste a intégré la liste des matériaux (meme si présente sur le site)